How Sony Sped Up A Factory With These Tiny, $35 Computers

Open a box with a Raspberry Pi and it may look like the rest of the laptop is lacking. Costing just $35, it’s a stripped-down circuit board protected with metal pins and squares, simply enough hardware to energy games and surf the Web. Hobbyists and technological know-how teachers were its first enthusiastic clients six years in the past, but now the standard Pi computer systems have a brand new fan base: producers and businesses.

The Raspberry Pi Foundation’s buying and selling the division, which has gifted £17 million ($22 million) closer to promoting pc science in schools, has visible demand for its reasonably-priced tool skew increasingly in the direction of business customers, Forbes has found out.

Hotel chains, garbage collectors and factories are the usages of the tool greater usually now, making up 50% of stop customers, and in some instances, the Pi is undercutting the industrial monitoring gadget sold by bigger agencies.

/cdn.vox-cdn.com/uploads/chorus_image/image/69595021/ajohnson_210712_4667_0002.0.jpg)

In Europe, a community of hydrogen refueling stations used to strength hydrogen cars, are now having their temperature and filling degrees monitored with the aid of Raspberry Pi’s to assist managers predict preservation, at the same time as at any other commercial enterprise the tool is getting used to concentrate to audio from elevators for any anomalies that recommend a restoration is needed.

One municipality in Africa is the usage of Pi’s to display the level at which rubbish containers are stuffed to decide whilst vehicles need to come through for series, at the same time as a motel chain changed into additionally getting ready to install them in rooms, according to anecdotes shared through analysts from research companies Gartner and Forrester.

One factory manager says the device is so reasonably-priced and effective that once a 3-yr trial it has helped make his computerized equipment 30% extra green, particularly within the velocity of manufacturing.

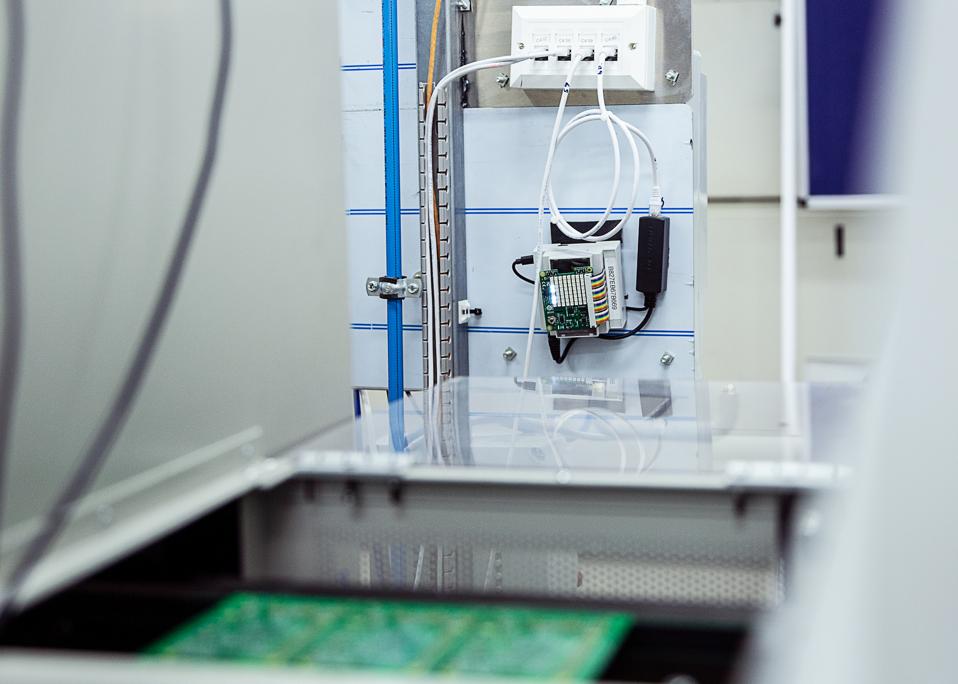

“It’s made us extra aggressive,” says Kevin Edwards, who heads engineering at Sony’s main manufacturing facility in Pencoed, Wales. In most instances, the Pi’s are getting used to screen system.

The manufacturing unit producers hair-elimination gadgets and $50,000 broadcast cameras for Sony, as well as the Raspberry Pi itself, and has hooked up 60 of the gadgets around its gleaming-white facility, each one about the dimensions of a % of cards.

The Pi’s clunky appears are a part of its appeal as something you may upload stuff to—or hack, in hobbyists’ parlance. Edwards has mounted the gadgets onto machinery or walls and plugged them into the nearest electricity source.

Each tiny pc is ready with more sensors to reveal things like temperature, vibration, proximity, and strength utilization.

As it spies on a bit of computerized equipment or robot, it then sends data to a database using a relaxed protocol that Edwards’ team developed. Some of the Pi’s have cameras that file a video feed of the machines which, as an instance, receives processed by using imaginative and prescient-popularity software to look for irregularities.

“It permits us to keep away from having to have someone painstakingly watch over a system,” says Edwards. “This is how we stop people strolling around with clipboards.”

Sony is now replicating his experiment in three different factories in Asia, consisting of in Japan and one in Malaysia, in order to additionally installation among 50 and 60 Raspberry Pi’s to monitor equipment there.

Monitoring machinery as Edwards has finished is the crux of a technology fashion that became in fashion for a while, called the Industrial Internet of Things. This mentioned the use of sensors and wireless connectivity to display machinery and weed out efficiencies through, for example, predicting whilst a robot arm needed protection earlier than it broke down.

“The undertaking is a return on funding,” says Dan Bieler, an analyst with Gartner who has tracked traits with an Internet of Things and noticed a reluctance to spend money on such generation. “We’ve visible a look for inexpensive alternatives.”

He’s heard of several divisional managers or center managers at industrial plant life who’re experimenting with the Raspberry Pi, frequently buying the device with their non-public credit playing cards.

The intention is taking pictures of the same types of efficiencies promised by using larger, greater-luxurious IoT groups like Siemens or manufacturing unit-automation specialist Omron.

The Pi charges five to 10 instances much less than comparable gadget from larger companies says factory-manager Edwards, who declined to name any of these groups.

“You want to test and fail to force meaningful innovation,” says Bieler of Gartner. “If you fail at $one hundred,000 it’s painful. If you fail and also you’ve spent $1,000, it’s an extraordinary form of failure.”

That could virtually be good for businesses like Siemens, he adds. When a person like Edwards experiments with the Raspberry Pi, it’s displaying evidence of a market for the Internet of Things era in the industry, which hasn’t but flourished inside the manner technologists have hoped.

Eben Upton didn’t count on any of this when he commenced the Raspberry Pi Foundation six years ago, or that he’d sell 25 million gadgets. Having first expected a trickle of preliminary orders from robotics fans, his tiny staff became beaten on the day they first went on sale. More than a hundred,000 human beings awakened at 6 a.M. U.K.-time to reserve one.

“We notion we were going to sell a thousand,” he says from his headquarters in Cambridge. “It becomes just hell.” Since that day, Raspberry Pi has delivered in about £25 million in licensing revenue, of which £17 million ($22 million) has long past to its charitable arm.

The buying and selling arm makes cash with the aid of promoting blueprints of the Pi for a few bucks every to 2 number one manufacturers. The business version is just like ARM’s, which designs the tiny processors which can be determined in maximum smartphones.

The Pi’s producers then store them online, alongside other resellers who are often mother-and-pop groups, says Upton.

One such business in Cambridge saw its founder max out a credit card to shop for £2,000 really worth of Raspberry Pi computers to promote. Last yr the commercial enterprise delivered in sales of £10 million, says Upton.

Upton estimates that the total revenue generated via his enterprise and others selling the physical gadgets is $200 million.

“The entire thing has grown organically,” he says. As a licensing commercial enterprise, it’s difficult to inform precisely who the Pi’s end customers are, but Upton confirms he’s been hearing about industrial use cases. Further evidence: The gadgets’ income at some stage in the year is becoming more strong, in place of just spiking at Christmas time.

There’s an added advantage for Upton. In making the Sony manufacturing facility greater efficient, it’s made generating the computer systems there easier to finances too, he says. “We construct in the U.K. Now not because it’s excellent but because it’s reasonably priced.”

Office Depot Laptops – What Are They?

Laptops are the most commonly used computer in the world and are very easy to buy. They ar…